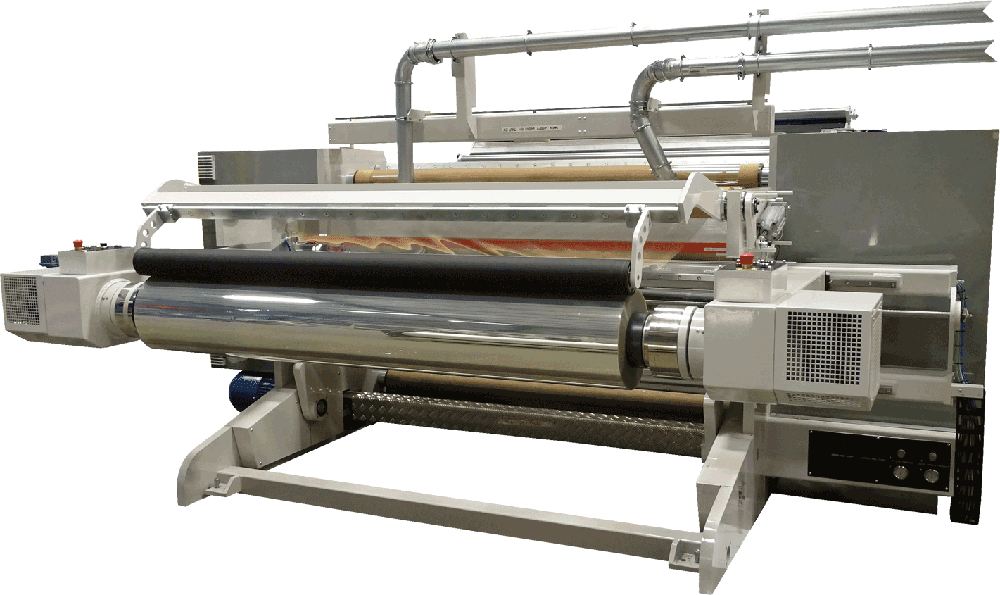

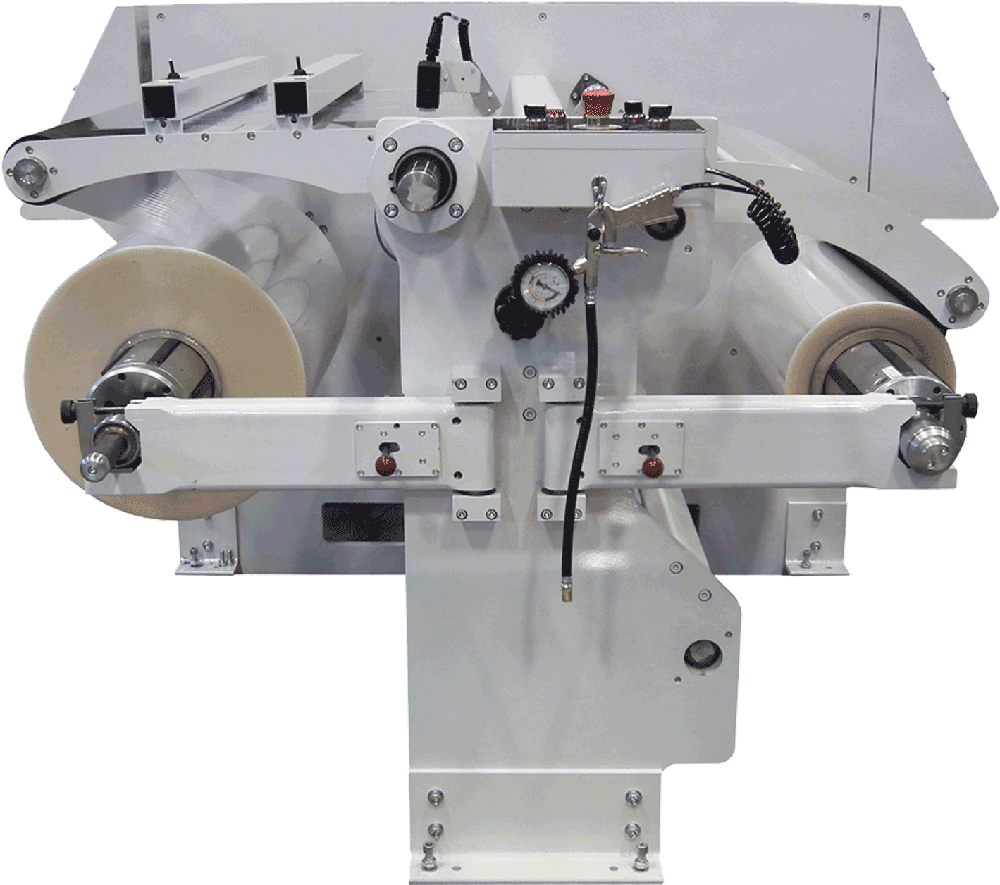

Emerald Doctor Rewinder

A wide-web doctor rewinder designed to minimise waste by transforming a badly wound roll, be it by tensions or roll profile, into a perfect grade A roll.

Enquiry

If you are interested in finding out more about our products, please fill out the following form and a member of our team will be in touch with you soon.

EmeraldWide-Web Rewinding / Doctoring Machine (Salvage Rewinder)

Minimising waste is a critical factor in today’s quest to limit the amount of scrap produced. Often, this scrap can be salvaged by processing the material through a doctoring machine.

The Emerald series of rewinders can transform a badly would roll – be it by tensions in a roll profile or poor edge quality – by re-rewinding the roll to remove issues.

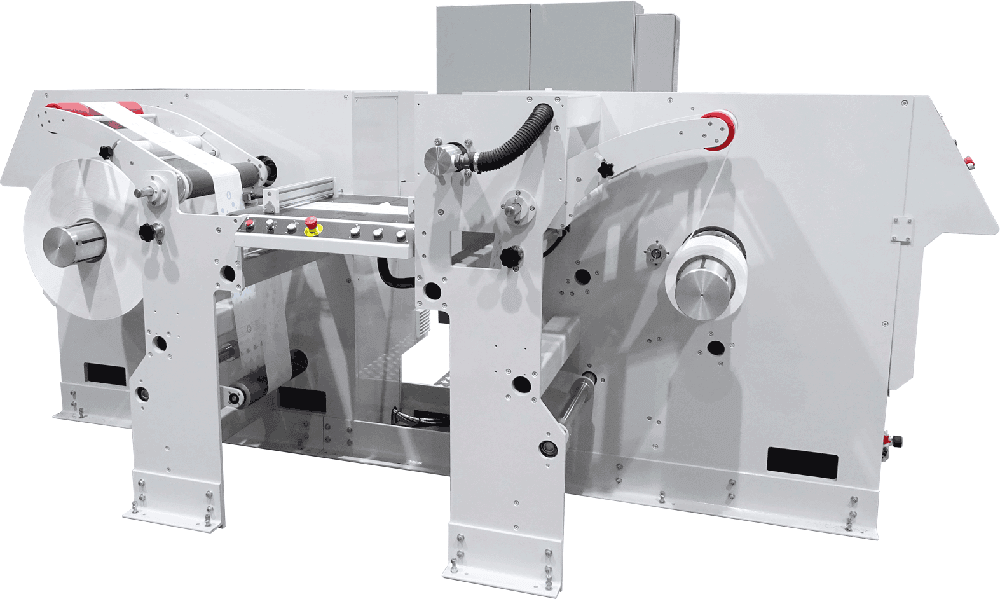

The doctoring machines can be configured to function in a single direction or to be fully reversible. They can also incorporate slitting stations for edge trimming, splicing tables and full 100% camera inspection systems for full product inspection.

- Features

- Specifications

- Gallery

- Video

- Brochure

- Able to cover a wide range of widths and diameters

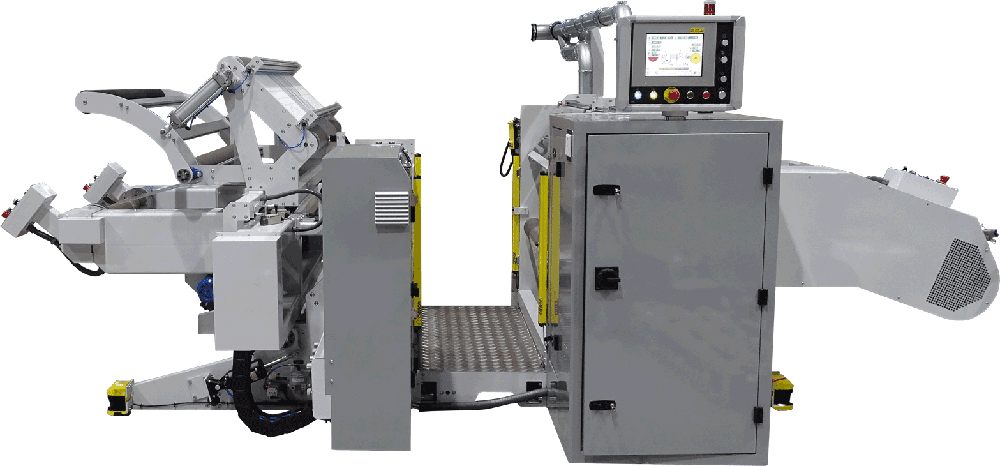

- Maximum speed of up to 800m/min (2625ft/min)

- Perfect tension control via pneumatic dancer control

- Fully reversible machines available without stopping to minimise downtime

- All electric operation

- Full layon control unwind rewind and unwind (if reversible)

- Slitting options available for edge trimming

- Range of inspection systems available from 100% camera systems to stroboscopes and backlights.

- Scrap winders available on machine

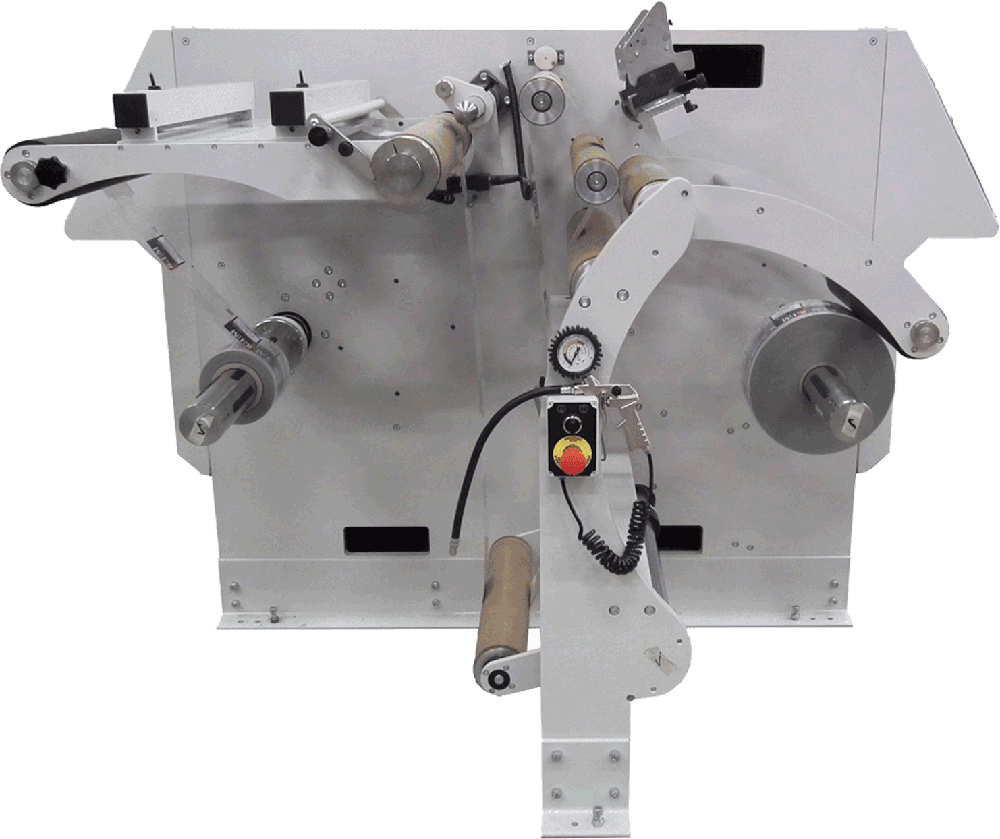

| Material widths | 300mm (12″) to 2500mm (98″) |

| Maximum unwind diameter | From 600mm (24″ to 1500mm (59″) |

| Maximum rewind diameter | From 600mm (24″ to 1500mm (59″) |

| Machine speed | Up to 800m/min |

- Various slitting methods available

- Available to handle a wide range of flexible films, laminates, non wovens and paper

Download this brochure as a PDF:

ASHE Product RangeDoctor RewinderKey Features

Get in touch

Discover why our clients choose us for their slitter rewinders and converting machinery.

Enquiry

If you are interested in finding out more about our products, please fill out the following form and a member of our team will be in touch with you soon.