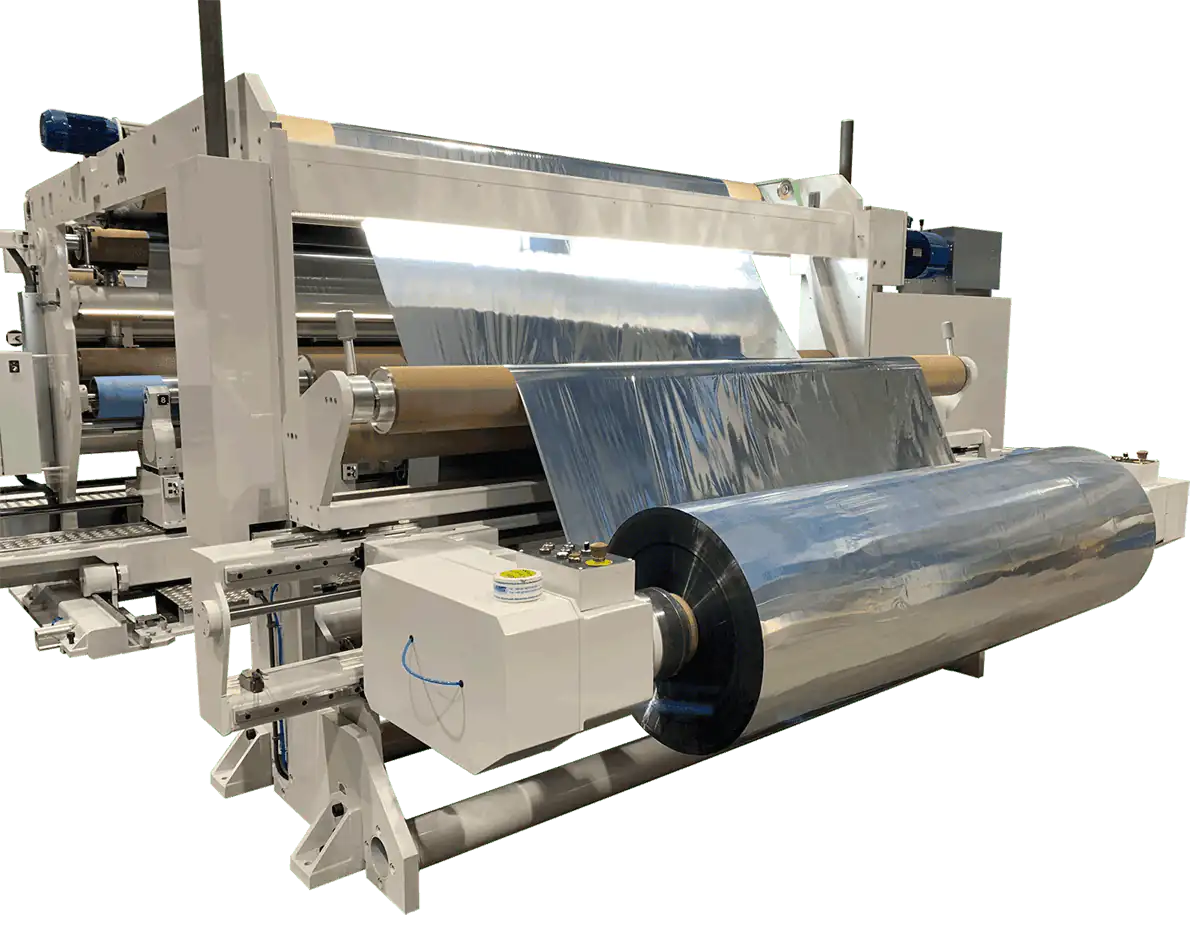

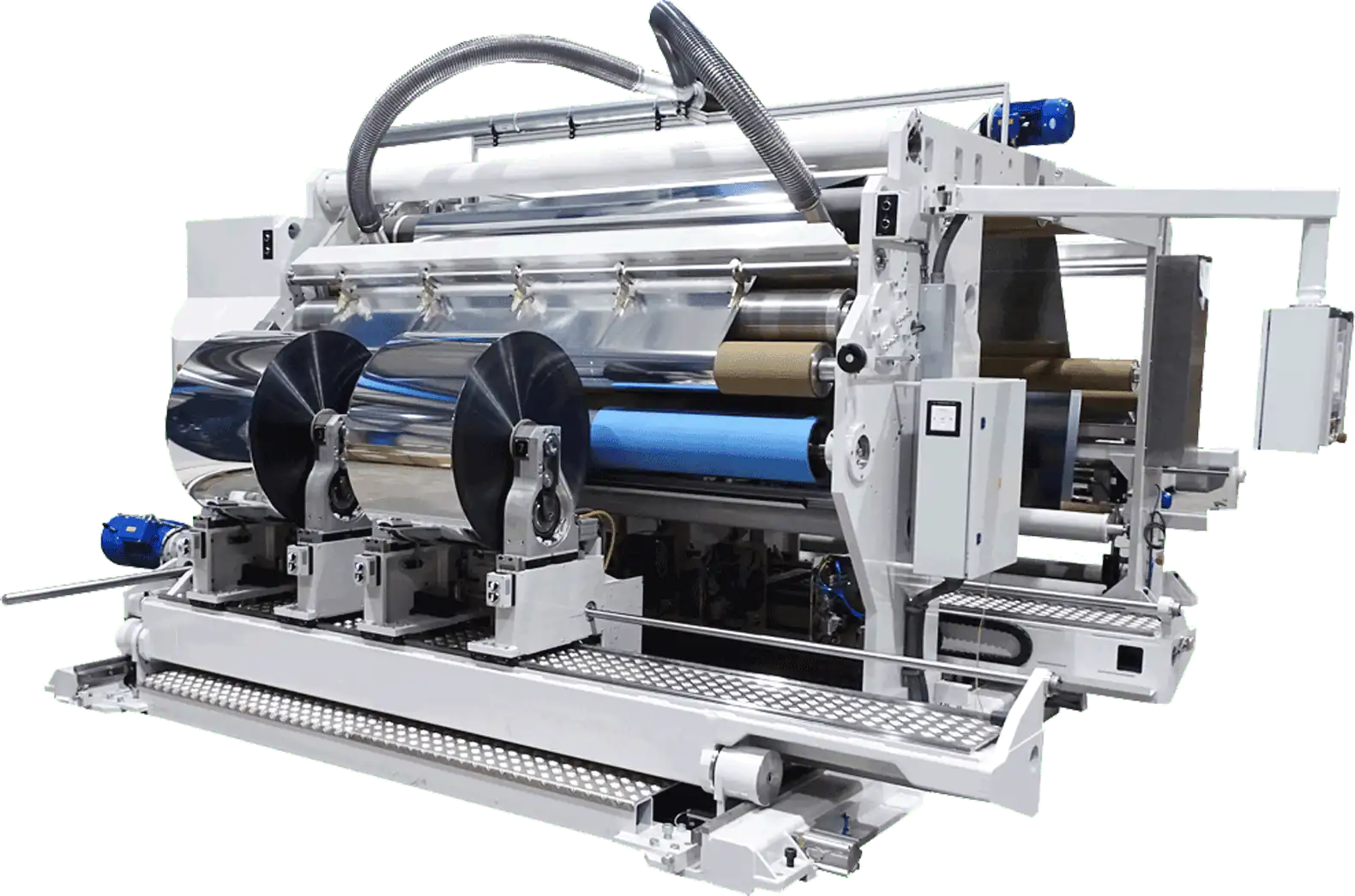

Jade Film Slitter Rewinder

The Jade series is engineered to enhance the winding quality of all films even at high speeds. Designed for maximum flexibility, it allows for seamless machine setup, making it one of the top secondary slitter rewinders available in the US.

Enquiry

If you are interested in finding out more about our products, please fill out the following form and a member of our team will be in touch with you soon.

JadeSecondary Film Slitter Rewinder

Our Jade secondary model slitter rewinder, featuring individual rewinding stations, is specifically developed for film manufacturers and converters seeking perfect finished roll quality in minimal time.

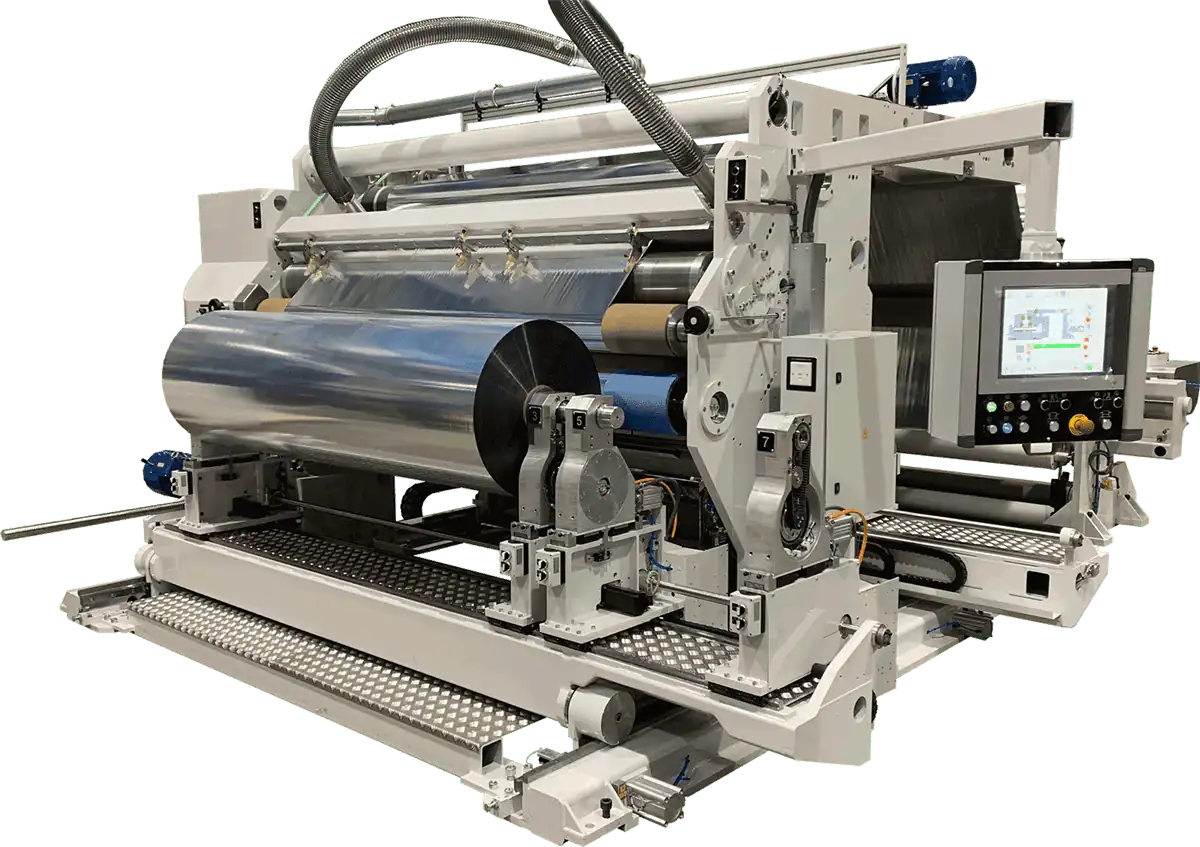

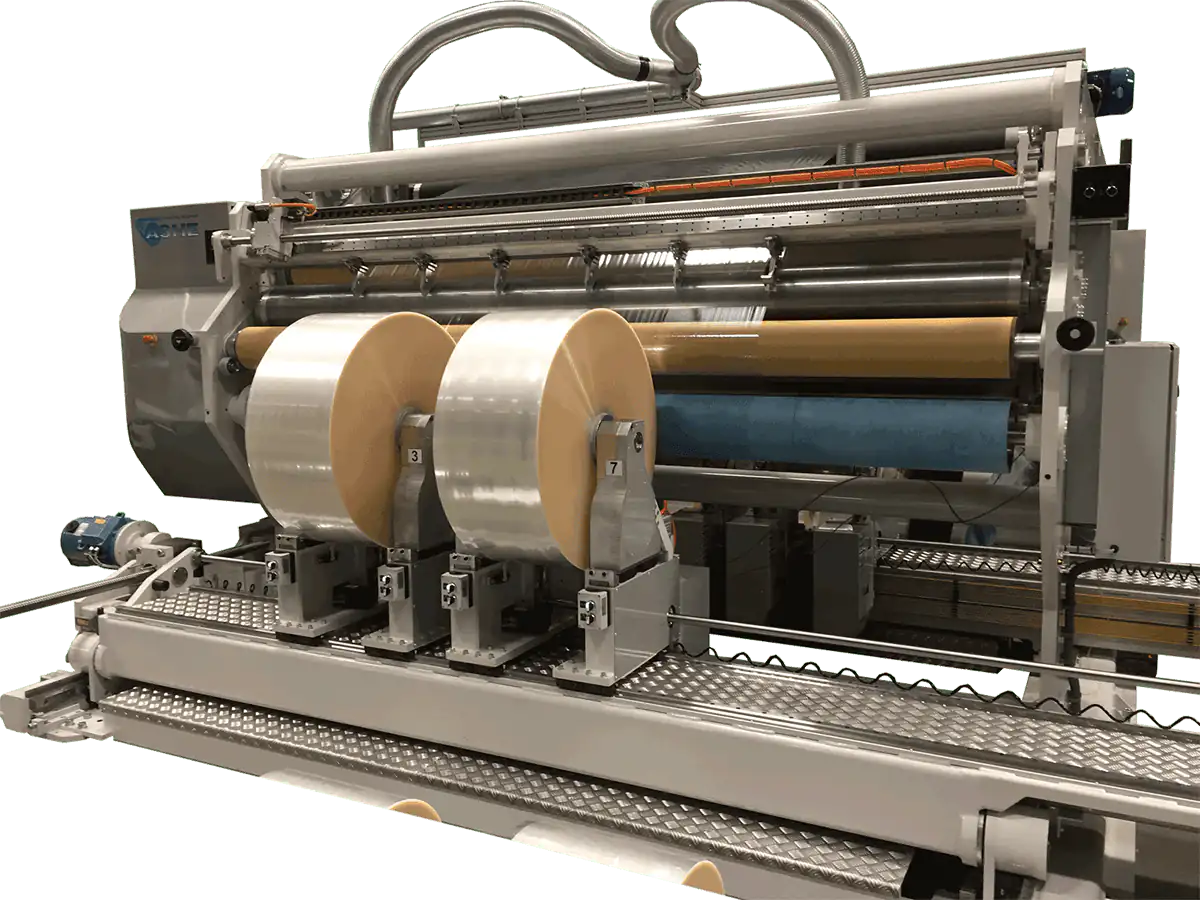

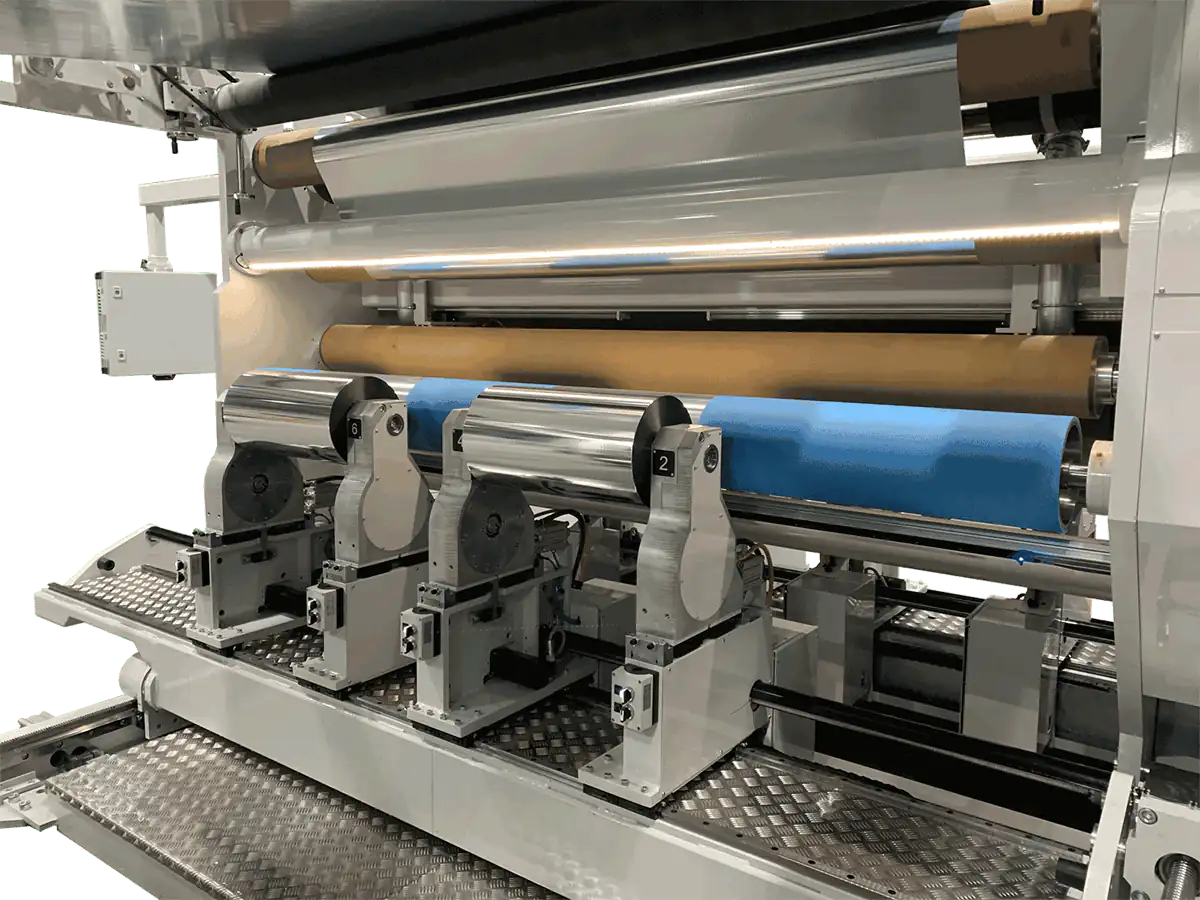

Built on our proven linear winding system, the machine uses a single contact (lay-on) roller per rewind beam, eliminating the need to adjust roller positions when changing slit patterns. A driven contact roller supports multiple winding configurations to ensure optimal roll profiles for various applications.

Designed for versatility, the Jade series accommodates all types of film manufacturers, including BOPP, CPP, BOPET, PA, metalized, and coated films. It can also be tailored for converters handling paper, film, laminates, and specialty products.

The machine offers a range of unwinding systems and slitting configurations, making it suitable for most substrates. Automation options include simplified automatic knife and rewind arm positioning, requiring minimal maintenance.

- Features

- Specifications

- Gallery

- Video

- Brochure

- Fully electric operation – no hydraulics required

- Easy installation and low maintenance

- Multiple slitting systems for diverse applications

- Vacuum roller for precise tension isolation

- Semi-automatic or fully automated knife and rewind arm positioning

- Full automation on knife and rewind arm setup also available

- Linear winding system, independent of the lay-on roller

- Flexible roll unloading options – from simple trolleys to full conveying systems

- Remote diagnostics for real-time monitoring

- Servo-driven rewind motors for precise control

- Supports center and center-surface winding

| Material width | Maximum 4000mm (158″) |

| Parent roll diameter (unwind) | Maximum 2500mm (98″) |

| Finished roll diameter (rewind) | Maximum 1200mm (48″) |

| Slitting methods | Razor Rotary Shear Burst |

| Minimum Slitting widths | 250mm (10″) |

| Maximum finished roll weight | 3000kgs (1363lbs) |

| Machine speed | Up to 1200m/min (3940ft/min) |

Download this brochure as a PDF:

ASHE Product RangeSecondary Slitter RewinderKey Features

About Duplex Turret Slitter Rewinders

Discover why our clients choose us for their slitter rewinders and converting machinery.

Enquiry

If you are interested in finding out more about our products, please fill out the following form and a member of our team will be in touch with you soon.