Sapphire S2T

This is the right choice of slitter rewinder for the converter looking for maximale Produktivität und minimale Stillstandszeit. Dies wird durch die Maschine erreicht weiterlaufend whilst the operator (or machine) takes off the finished rolls and puts new cores onto the rewind shaft.

Anfrage

If you are interested in finding out more about our products, please fill out the following form and a member of our team will be in touch with you soon.

Sapphire S2TBreitbahn-Duplex-Wendeschneidwerk-Aufwickler

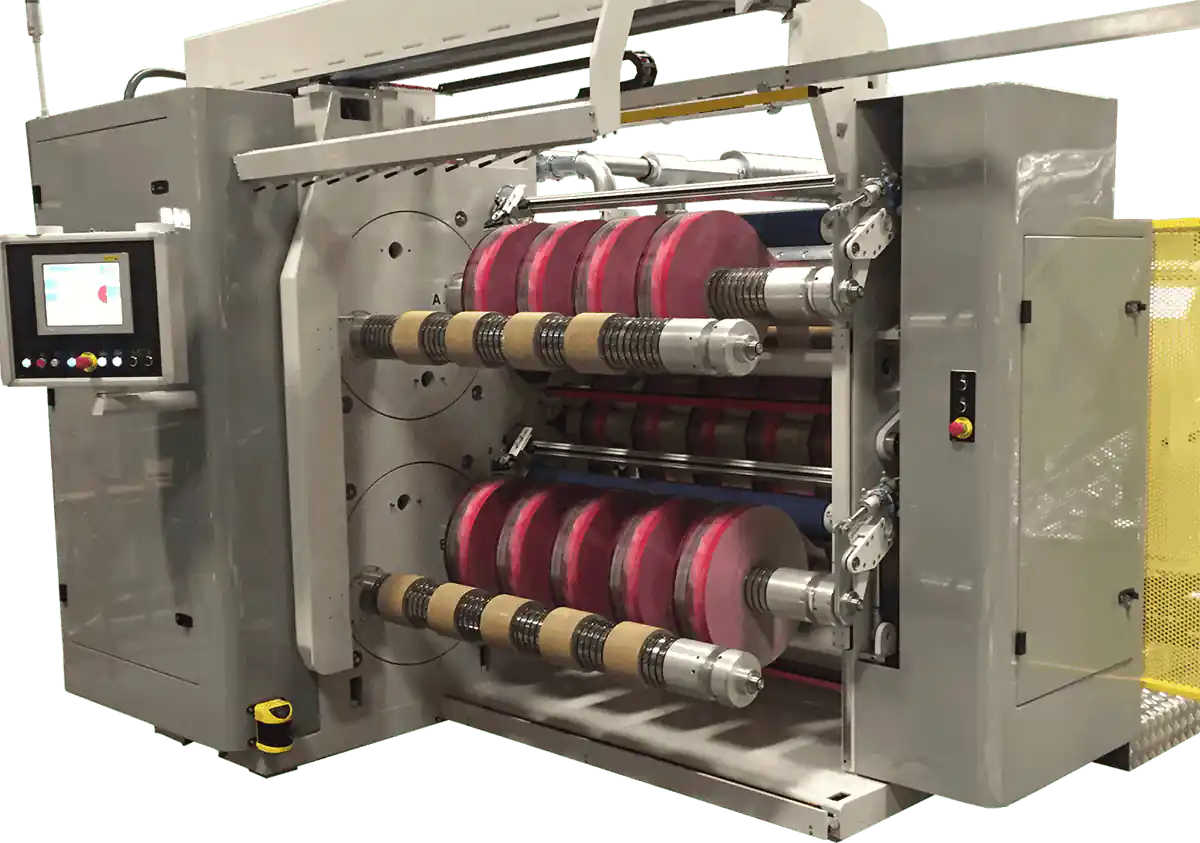

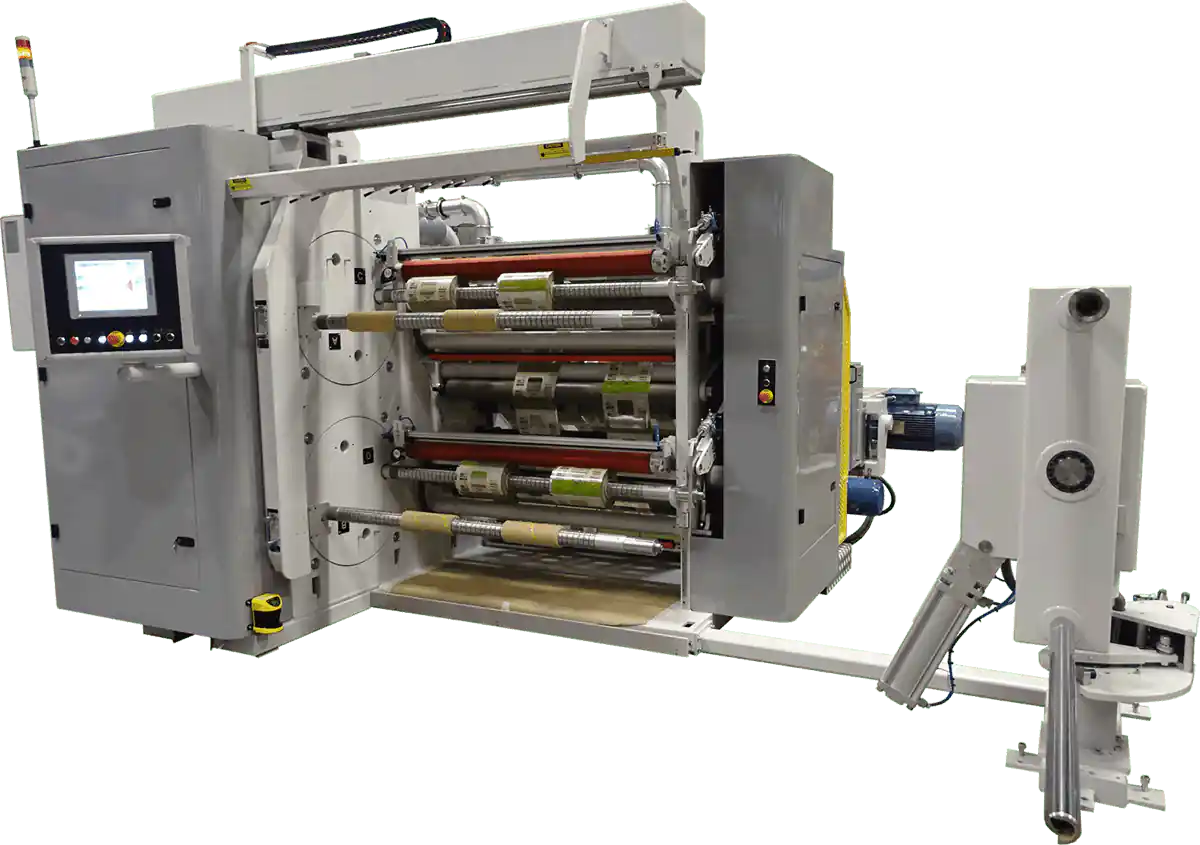

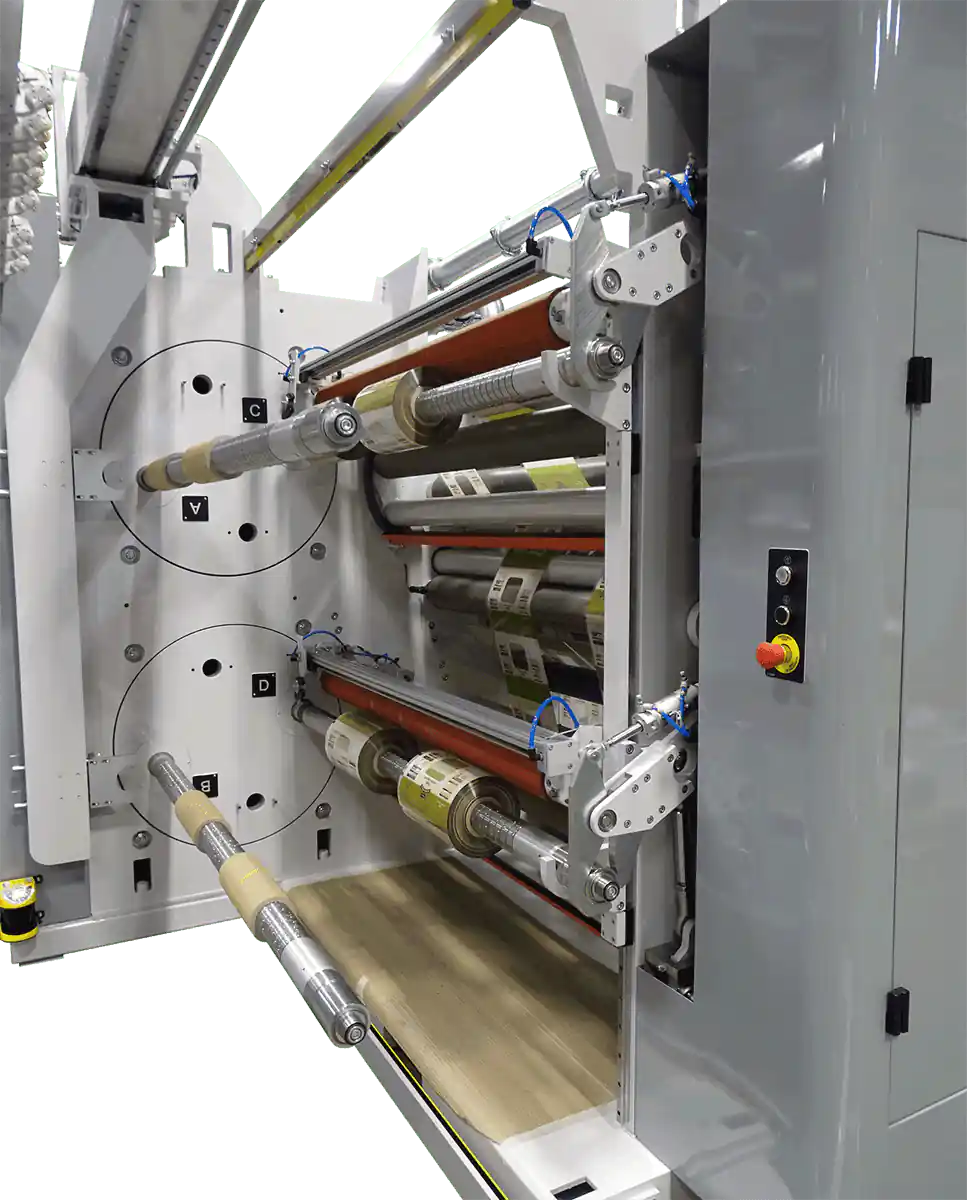

The key benefit of duplex turret slitter rewinders for users is productivity. This is achieved by the machine continuing to run whilst the machine, or operator, is offloading finished slit rolls and re-coring the rewind shafts. On duplex machines, the machine is not running; however, this loss of productivity can be reduced on a duplex turret slitter rewinder type of machine as the four rewinding shafts (two on each turret ring) ensure that the machine continues to run whilst these procedures are taking place.

The design of the Sapphire S2T is based on our Sapphire S2 duplex machine. No hydraulics on the machine makes it a clean operation for flexible packaging and medical applications, and the latest control technology makes the machine easy to use, with a minimal web path length. Easier and quicker setup times can also be implemented on the machine with further automation options, such as automatic knife and rewind core positioning systems.

The machine incorporates our unique ‘turret shaft support’, which ensures that the rewind shafts remain fully supported through the turret cycle. Due to this support, the machine is able to offer very fast cycle times, from the time the machine stops when the set length has been reached to the time it starts the next run.

The versatility of being able to run different substrates with no operator intervention or maintenance is achieved through our vacuum roller along with our driven lay-on roller system.

A range of roll-handling solutions on the rewind side of the machine can also be implemented on the machine, from simply fixed pedestals though to full robotics.

- Merkmale

- Spezifikationen

- Galerie

- Video

- Broschüre

- Getrennte wellenlose Abrollung mit unabhängiger Bewegung der einzelnen Arme

- Electric roll lifting system, which uses no hydraulics

- Gebremste Abrollung oder angetrieben mit Tänzerrolle

- Spleißtisch auf der Abrollung für Rollenverbindungen

- Full web guiding with ASHE’s own edge/line guide for all materials

- Vakuumrolle zur Spannungsisolierung

- Alle Arten von Schlitzen können auf der Maschine untergebracht werden

- Full automation can be offered with automatic knife/blade positioning available for all forms of slitting

- Laser-aided positioning or digital readout systems available for slitting

- ASHE differential (friction) winding shafts, which require NO LUBRICATION

- Systeme mit offenem oder geschlossenem Regelkreis für die Steuerung der Aufwickelspannung

- Motor und Antrieb auf jeder Aufwickelwelle als Standard

- Driven lay-on (contact) roller system with different widths available

- Intuitives HMI mit Speichermöglichkeit

- Volle Ferndiagnose mit Datenübertragungsmöglichkeiten

- Unabhängige Motoren und Antriebe für jede Aufwickelwelle

- Vollständiges Stützsystem für den Turmschaft

- Automatic cross-cut system

- Extrem kurze Zykluszeiten des Revolvers

| Materialbreite | 1000mm (40″) to 2000mm (80″) |

| Durchmesser der Mutterrolle | 1800mm (71″) |

| Maximaler Aufwickeldurchmesser | 450mm (18″) & 600mm (24″) |

| Schlitzmethoden | Alle Schneideverfahren verfügbar |

| Schnittbreiten | Minimum 25mm (1″) |

| Geschwindigkeit der Maschine | 800m/min (2620ft/min) |

Laden Sie diese Broschüre als PDF herunter:

ASHE ProduktpaletteSapphire S2T Rollenschneider AufwicklerHauptmerkmale

Sind Sie bereit?

Entdecken Sie, warum unsere Kunden uns für ihre Rollenschneidmaschinen und Verarbeitungsmaschinen wählen.

Anfrage

If you are interested in finding out more about our products, please fill out the following form and a member of our team will be in touch with you soon.